-

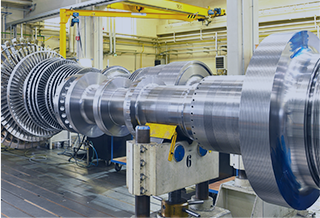

We integrate products with cutting-edge technology to support excellence in Japanese advanced manufacturing.

We contribute to reform and efficiency improvements in manufacturing.3D printers and Additive Manufacturing technology can greatly simplify the supply chain and improve product functionality. Automated layup systems for composite prepreg are at the forefront of realizing full automation in manufacturing equipment.Clean laser is a high-precision system for surface processing that does not require media and creates no waste. Please feel free to contact us for more details.

Please feel free to contact us with any questions

from the e-mail form.

-

Aligned Vision(ex ASSEMBLY GUIDANCE SYSTEMS)

Aligned Vision’s laser projectors are widely used in the aerospace industry, and also for wind power generation blades, F1 racing cars and shipbuilding. For manual layup on a jig for composite manufacturing, the shape data of each ply in a CATIA model is converted into laser projection data by separate custom software, and the necessary ply data is projected sequentially based on the data, therefore reducing the number of template changes and labor costs.

-

Clean Laser Systems

With over 20 years of experience in laser cleaning technology development and manufacturing, Clean Laser has installed more than 1,800 units in the fields of aviation, automotive, food, electric power, infrastructure, etc., and have the latest technology in metal cleaning, paint peeling, pre-adhesion treatment, etc.

-

TPAC(日本代理店 dB)

DB Co., Ltd. specializes in ultrasonic flaw detection equipment using FMC / TFM, also known as aperture synthesis. This advanced technology can support detection of items previously thought difficult, such as detection and sizing of aluminum alloy plates with acoustic anisotropy, austenite welds, inside controlled rolled steel, oblique scratches and stress corrosion cracks with unclear directions, use of low frequency probes, and detection of fine scratches on ultrasonic attenuation materials (cast products, etc.).

-

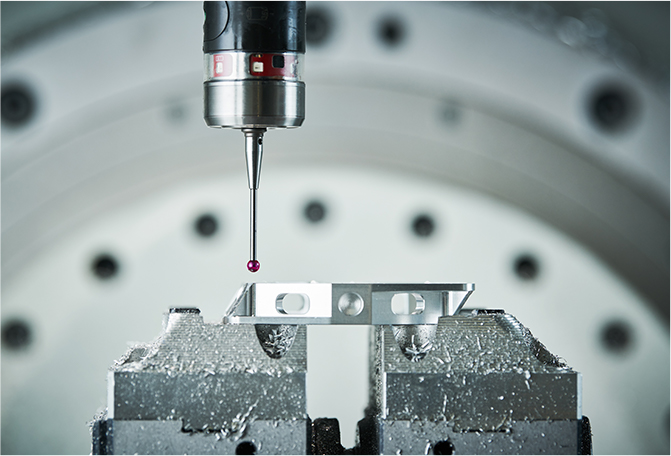

UNITED SCIENCES

Aeroscan™, made by United Sciences, is a non-contact 3D scanner that can measure aircraft fastener holes in a few seconds with a handheld device or mounted on a robot for automated use with multi-function end effectors. The 3D scanner probe takes a series of precise hole measurements (diameter, countersink diameter, countersink depth, coaxiality, grip length, perpendicularity, mixed material stacks). Bore diameters are measured to within 5 microns (0.0002″) of accuracy and repeatability.

-

Cevotec

Cevotec is a German manufacturer of equipment that cuts carbon fibers into patches and automatically lays them up. This process is suitable for small and complicated composite parts, which is conventionally performed by hand lamination. Cevotec developed their own original software that enables improved yield, lighter product weight, and shorter cycle time with optimum patch layout.

Please feel free to contact us with any questions

from the e-mail form.