CEVOTEC

Cevotec Fiber Patch Placement System

Fiber patch placement is suitable for manufacturing three-dimensional preforms with complex curved surfaces, which is difficult to lay-up with conventional automatic lay-up equipment using continuous fibers. Roll-shaped tapes such as CFRP, GFRP, and film adhesive are cut into a shape, and the cut patches are automatically laid-up on the mold. By arranging the fibers along the load direction, the strength of the fibers is maximized and weight reduction while maintaining strength is possible. In addition, by automating the lay-up of complex-shaped parts, which used to be mainly manual work, quality control is improved while manufacturing costs are reduced.

-

Applications

Since it is possible to process up to four different materials in a single device, it is possible to efficiently manufacture parts using different materials such as honeycomb structure parts. Other applications include the manufacture of aircraft and automobile parts where weight reduction is required, and it is also suitable for reinforcing the dome of hydrogen fuel tanks.

-

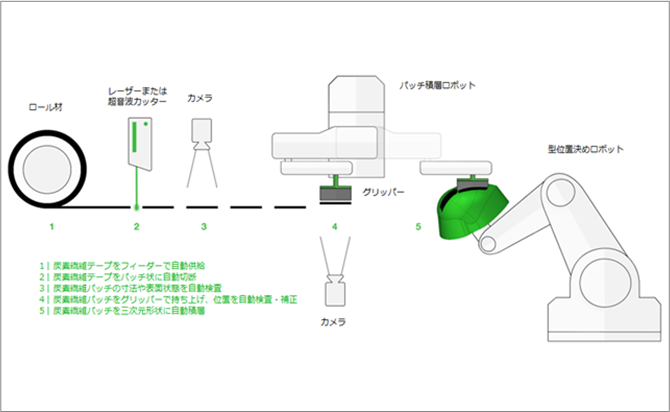

Main component devices (Example of SAMBA Pro)

Each cut patch is fed to the gripper after image inspection by a camera. Out-of-tolerance patches are collected in a waste tray and are not used for part layup. The relative position of the patch to the gripper is recognized by the camera, and the position is corrected during the transfer to the mold.

-

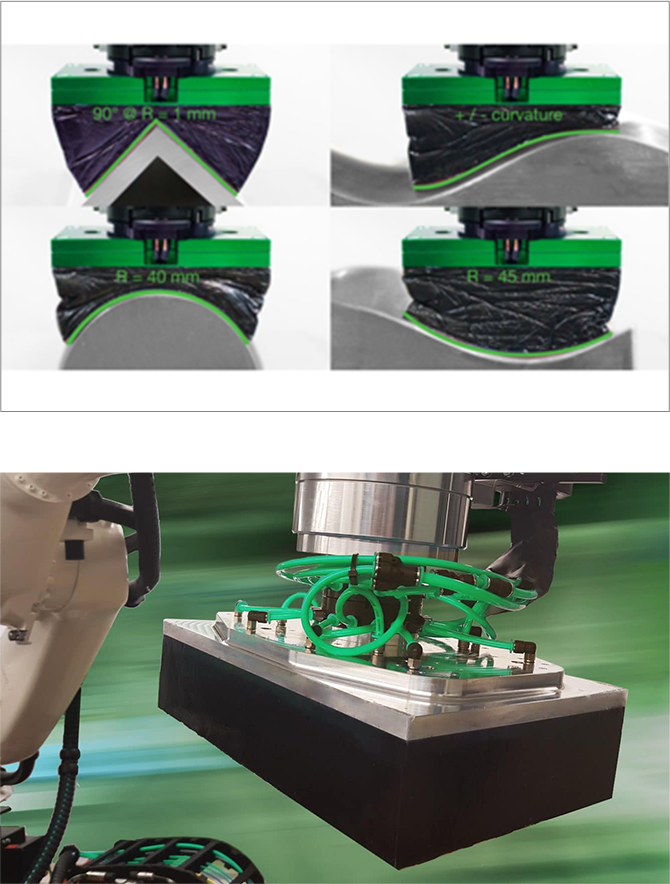

Gripper

The flexibility of the gripper is very high, making it possible to lay up patches on molds with complex curved surfaces. The size of the gripper can be customized according to the shape of the product, and is currently available in sizes equivalent to A4 (200x300mm), with the ability to automatically exchange grippers of different sizes.

-

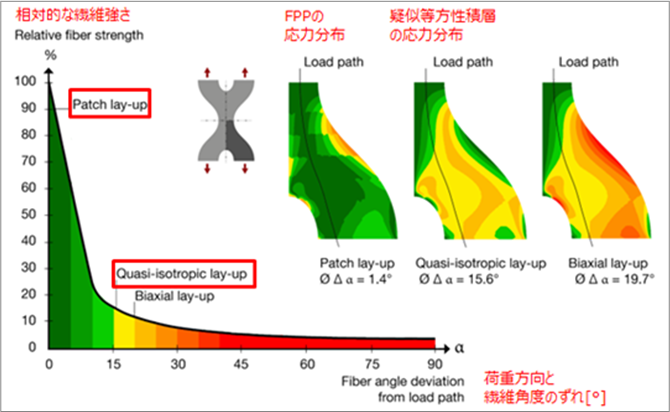

Advantages of FPP compared to continuous fiber

In quasi-isotropic lay-up using continuous fibers, the inherent strength of the fibers cannot be fully utilized due to the shape of the part. In the specimen shown in the figure above, if the angle between the direction of the stress generated in the part by tensile loading and the fiber direction is 15° on average, the strength will be less than 20% of the fiber strength. FPP, on the other hand, has a smaller angle opening of 1.4° on average and exhibits nearly 90% of the fiber strength.

-

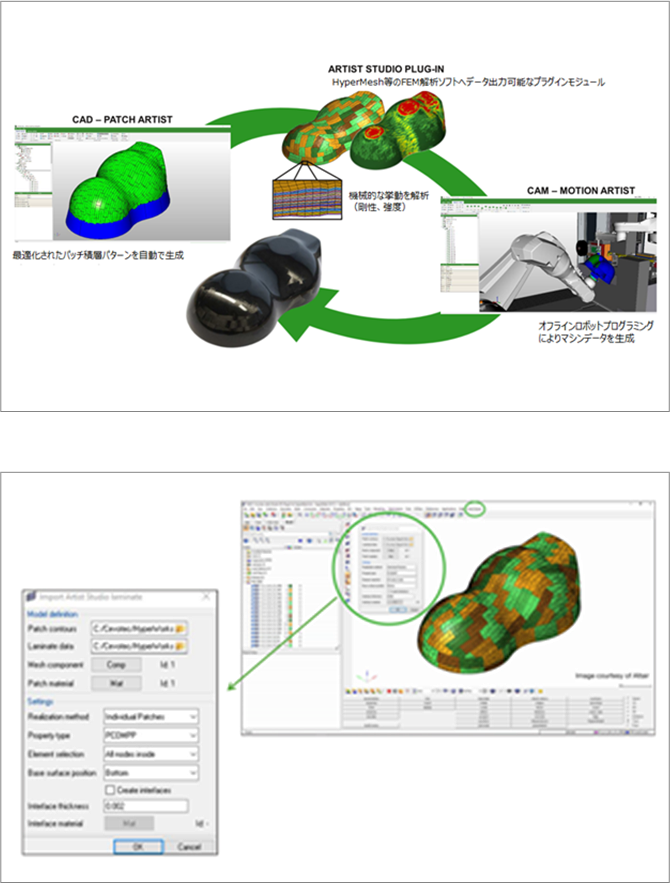

ARTIST STUDIO - Digital Manufacturing Process Software

To maximize the potential of FPP technology, Cevotec has developed a suite of software products called ARTIST STUDIO.

CAD-PATCH ARTIST

"This is the laminate design module of ARTIST STUDIO. Anyone can easily create a laminate by following the tree structure and making various settings in order from the top. The load path, which determines the direction of the laminate, can be created as a spline curve from another CAD system or as a guide curve from CAD geometry loaded in PATCH ARTIST.

(File formats that can be imported: STEP, IGES, STL, CATPart-cost option)

CAM-MOTION ARTIST

This module performs patch lay-up simulation and program output. It has an interference check function that allows you to visually confirm safety in the simulation, thus greatly reducing the time required for manufacturing preparation.

ARTIST STUDIO PLUG-IN

This is a plug-in module for commercially available FEM analysis software to automatically create patch lay-up models as defined by PATCH ARTIST, and to verify the fiber direction of each patch and the thickness distribution due to gaps and overlaps.

-

SAMBA Series

Tape feed & cut units, patch lay-up robots, and lay-up mold holding units can be freely combined to suit the application.

Please feel free to contact us with any questions

from the e-mail form.