-

We handle composite materials for manufacturing and repair of aircrafts from European and American manufacturers according to the required standards.

We import and sell advanced products such as composite materials used for manufacturing and repairing aircraft, helicopters, engines, components related to composite materials, tools, etc. from manufacturers mainly in Europe and the United States according to required standards and applications.

Please feel free to contact us with any questions

from the e-mail form.

-

HEXCEL CORP.

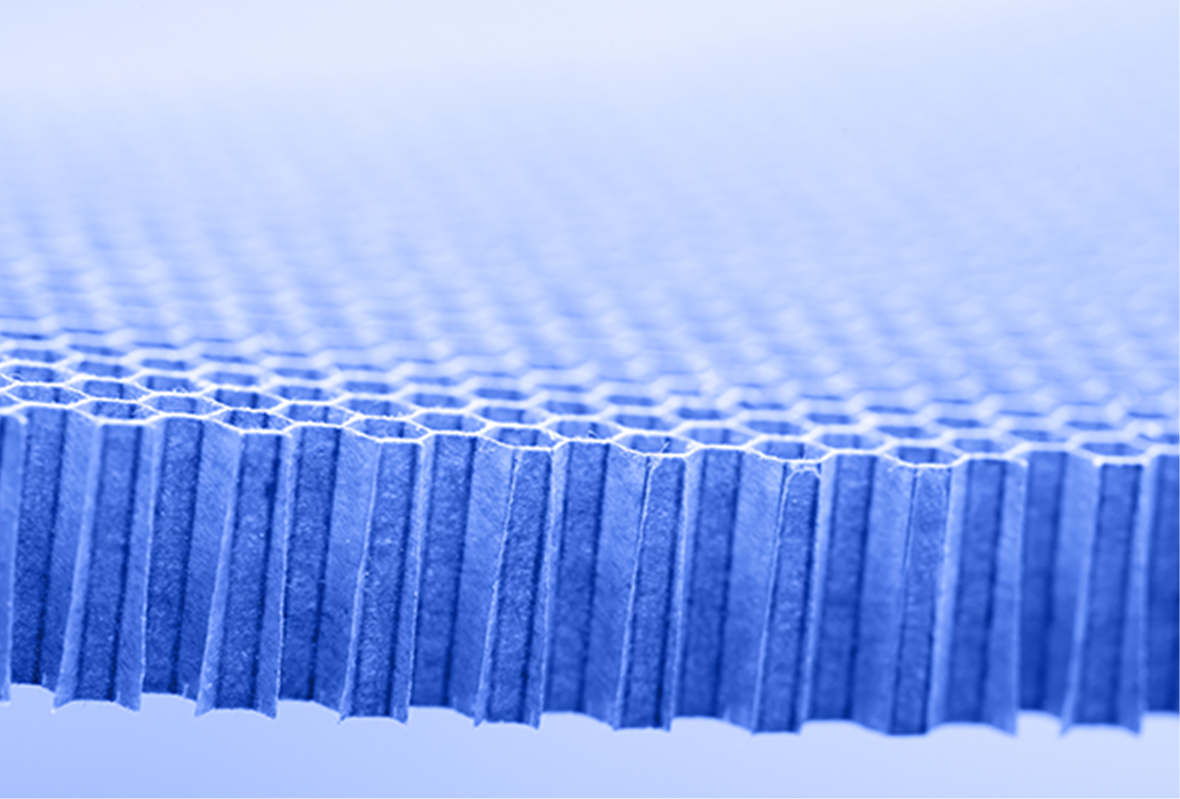

Hexcel’s product lineup includes: prepregs, honeycomb cores, adhesives, molding jig materials, thermoplastic materials, etc. Hexcel can also manufacture honeycomb molded products (Engineered Core) based on custom drawing requirements.

-

NIPPON YAKIN KOGYO CO., LTD.

NYK is a specialty steel manufacturer that makes Invar material (NAS36) with a low coefficient of thermal expansion suitable for tooling used for layup of composite materials. We have a long track record of supplying Invar to major Japanese heavy industry customers for aircraft manufacturing applications.

-

ALBANY INTERNATIONAL CORP (ex Exelis)

Albany Engineered Composites supplies highly reliable composite structures and components to major airframe and engine manufacturers, mainly in Europe and the United States, with a wide range of support from design, manufacturing and integration of commercial and military composite structures for airframes, engines, wings, tanks, etc.

-

Aligned Vision(ex ASSEMBLY GUIDANCE SYSTEMS)

Aligned Vision’s laser projectors are widely used in the aerospace industry, and also for wind power generation blades, F1 racing cars and shipbuilding. For manual layup on a jig for composite manufacturing, the shape data of each ply in a CATIA model is converted into laser projection data by separate custom software, and the necessary ply data is projected sequentially based on the data, therefore reducing the number of template changes and labor costs.

-

Convergent Manufacturing Technologies

Convergent makes composites processing predictable and low risk. Products and services include: composite parts simulation software, evaluation of curing degree, gelation, and glass transition, temperature during curing, balance evaluation of low thermal mass and heat generation control, resin flow analysis, stress analysis, calculation of deformation simulation and tool correction, local thickness analysis, fiber density analysis, and saturation prediction of resin flow rate.

-

Heatcon Composite Systems

Heatcon is a manufacturer of aerospace composite repair equipment including a full range of hot bonders, accessories, technical training services, and materials for the repair of composite structures. In Japan we supply vacuum heat bonds and superheater blankets for repairing CFRP parts for aircraft.

-

Cevotec

Cevotec is a German manufacturer of equipment that cuts carbon fibers into patches and automatically lays them up. This process is suitable for small and complicated composite parts, which is conventionally performed by hand lamination. Cevotec developed their own original software that enables improved yield, lighter product weight, and shorter cycle time with optimum patch layout.

-

Clayton Associates

Achieve a clean work environment! Clayton is an industry leader in hazardous dust control solutions, including polishing and cutting tools with vacuum suction and removal functions for paints containing heavy metals such as hexavalent chromium, lead, cadmium, aluminum scraps, carbon fibers, ceramic chips, glass fibers, and mold. Clayton strives to protect the health and safety of workers.

-

TPAC(日本代理店 dB)

DB Co., Ltd. specializes in ultrasonic flaw detection equipment using FMC / TFM, also known as aperture synthesis. This advanced technology can support detection of items previously thought difficult, such as detection and sizing of aluminum alloy plates with acoustic anisotropy, austenite welds, inside controlled rolled steel, oblique scratches and stress corrosion cracks with unclear directions, use of low frequency probes, and detection of fine scratches on ultrasonic attenuation materials (cast products, etc.).

-

UNITED SCIENCES

Aeroscan™, made by United Sciences, is a non-contact 3D scanner that can measure aircraft fastener holes in a few seconds with a handheld device or mounted on a robot for automated use with multi-function end effectors. The 3D scanner probe takes a series of precise hole measurements (diameter, countersink diameter, countersink depth, coaxiality, grip length, perpendicularity, mixed material stacks). Bore diameters are measured to within 5 microns (0.0002″) of accuracy and repeatability.

Please feel free to contact us with any questions

from the e-mail form.