GALA INDUSTRIES,INC. [Centrifugal Dryer]

Gala Industries (MAAG Group) Centrifugal Dryer

~GALA CENTRIFUGAL DRYER~

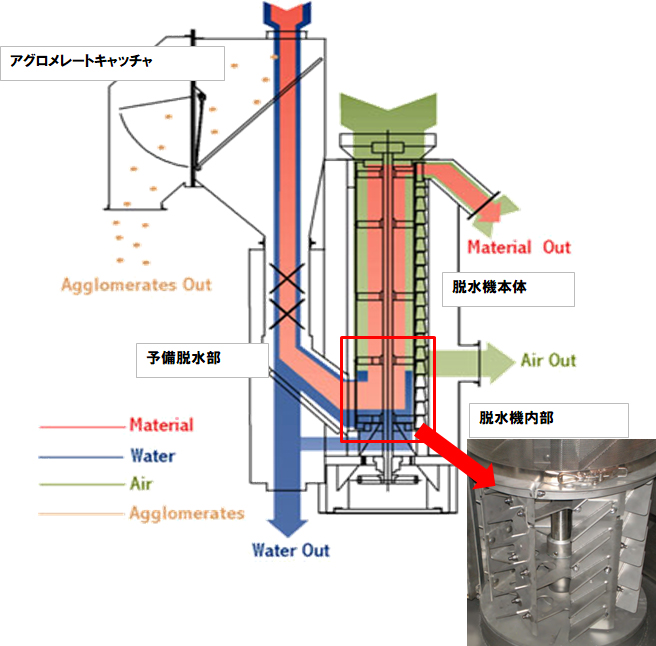

[Pellet dehydration mechanism]

The pellets produced in the upstream cut section and circulating water flow into the downstream dryer section.

1. The agglomerate catcher installed in front of the dryer removes lumps and string-like resin that are generated immediately after the start of production.

2. After 90-95% of circulating water is removed in the pre-dewatering section, pellets and a small amount of water flow into the dryer body.

3. Inside the dryer, the rotor with lifters (blades) rotates at high speed, and by flipping the pellets and colliding with the surrounding punching screen, it removes water (impact dehydration) and pushes it upwards, and finally. It is discharged to the outside from the pellet chute.

Furthermore, by utilizing a blower, the outside air is taken into the inside of the dryer, the pellets are blown, and the steam inside the dehydrator is exhausted, thereby exhibiting high dehydration performance. The heat of the pellet itself also affects the moisture content.

[Characteristics of Gala's Dryer] Gala has been manufacturing centrifugal dryers for pellets for over 50 years, and has grown to become the world's largest centrifugal dryer manufacturer. The main reasons are as follows.

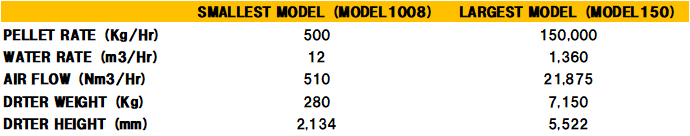

■ Extensive Lineup

from small size (~500kg/hr) to extra large size(max 150,000kgs/hr), low noize, high maintenance specifications

■ High Efficiency, Low moisture contents

Efficient construction to realize max dehydration ratio with least energy, high quality and high dulability. Surface moisture ratio of minimum 0.05wt% is guaranteed *Conditions apply for guarantee.

■ Diverse Sales Record

We have a proven track record in a wide range of applications, including applications for the recycling of fluff and film, low specific gravity products such as foamed materials, highly adhesive pellets, and fragile materials.

■ Maintenance-oriented design

The door is designed to be as large as possible for easy access to the interior and cleaning, and for easy partial repair or replacement of internal parts.

[Applications/Experience]

■ Applicable materials

・ General plastic and rubber

・ Foaming Resin (EPS, EEP)

・ Pellet, Chip and flake materials

■ Applicable processes

Raw material production/compounding/recycling/cleaning/mini-pellets/pre-dehydration of bulk/removal line for chips contained in products/research and testing facilities/pelletizing processes using water such as underwater cutting, hot cutting, mist cutting, etc.

■ Sales History

Gala has delivered over 8,000 units of Centrifugal Dryers all over the world. More than 400 units are operated in Japan, imported and delivered since 1975.

[Product Specification]

[Contact/ Product information download]

- If you have any questions, please feel free to contact us using the email form.

- Please fill out the required fields and download the detailed product informaiton (PDF)

Please feel free to contact us with any questions

from the e-mail form.